20150505 Bond Efficiency-GMG-ICE-v1-r04 Determining

网页2020year9month24day µm. Note that—in order for no correction factor for ball mill product fineness to apply—the ball mill circuit P80 should be no less than approximately 70 µm (Bond, 1962). This Bond Efficiency determination should not be applied to cir-cuits with a

Үйлчилгээ

Quantifying the energy efficiency of fine grinding circuits

网页2021year11month25day In this example, the OWi of the SAG mill was found to be 30% higher than the ball mill, thus suggesting that the SAG mill was less efficient than the ball mill.

Үйлчилгээ

Bond Grinding Circuit Efficiency - ceecthefuture

网页2018year2month20day Meeting of Bond Efficiency Guideline Working Group of the Global Mining and Standards Group Salt lake City, 2014 Based on Presentation to the 2008 Meeting of

Үйлчилгээ

Ball milling: a green technology for the

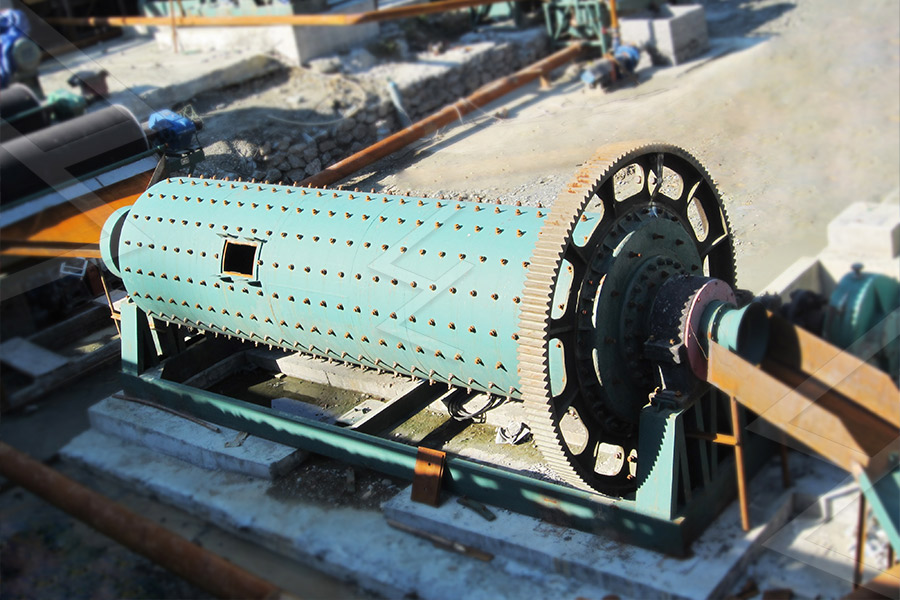

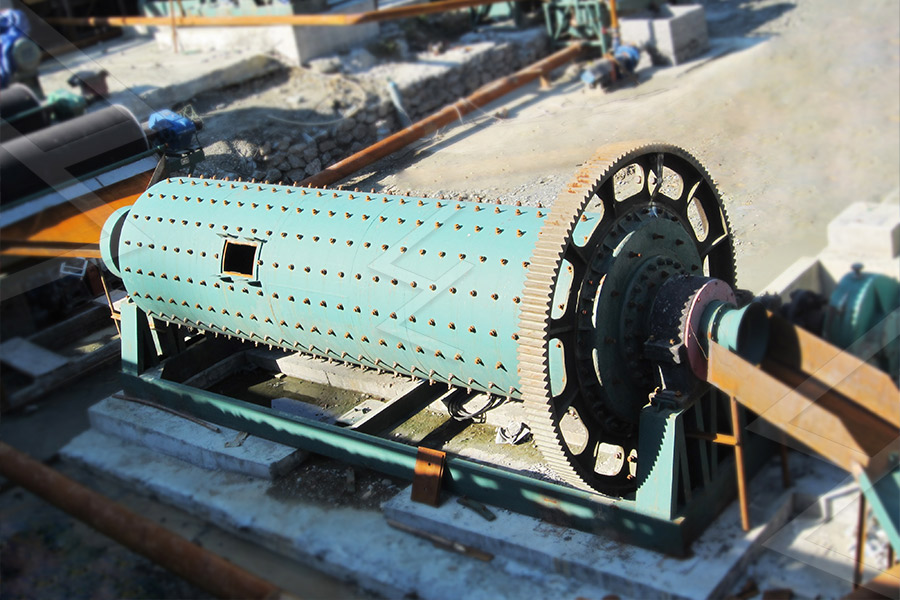

网页The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentally-friendly, cost-effective technique, it has found wide

Үйлчилгээ

Ball Mill Design/Power Calculation - Mineral

网页2015year6month19day The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be

Үйлчилгээ

Closed circuit ball mill – Basics revisited - ScienceDirect

网页2013year4month1day The reference point is a conventional ball mill circuit in closed circuit with cyclones operating at 250% circulating load and having 38% of fine material reporting to

Үйлчилгээ

Measurement of electrical energy consumption in a Bond

网页2011year1month1day The digital energy meter was previously tested and evaluated in Bond ball mill Work Index testing where direct measured comminution energy of ores processed in

Үйлчилгээ

Factors Affecting Ball Mill Grinding Efficiency

网页2017year10month25day a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that

Үйлчилгээ

(PDF) Energy Efficient Ball Mill Circuit

网页2013year7month15day The samples, once broken, can be used subsequently for Bond ball mill work index or batch grinding tests, therefore limiting overall sample requirements.The test generates an index (DWi) that can ...

Үйлчилгээ

A Comparative Study of Energy Efficiency in Tumbling

网页An evaluation of Relo grinding media (RGM, Reuleaux tetrahedron-shaped bodies) performance versus standard grinding media (balls) was made through a series of

Үйлчилгээ

Bond Grinding Circuit Efficiency - ceecthefuture

网页2018year2month20day Meeting of Bond Efficiency Guideline Working Group of the Global Mining and Standards Group Salt lake City, 2014 Based on Presentation to the 2008 Meeting of SME, by ... • Bond Test WI’s (kWh/t): Crushing:16.0 Rod Mill: 14.5 Ball Mill: 13.8 • Bond Standard Circuit Work Index: W Total = 0.9 + 3.4 + 8.0 = 12.3 kWh/t = 14.1 kWh/t Note:

Үйлчилгээ

Closed circuit ball mill – Basics revisited - ScienceDirect

网页2013year4month1day Based on experience acquired over the years and the investigative work conducted by F.C. Bond, it was established that the optimum circulating load for a closed ball mill – cyclone circuit is around 250%. This value is used as guideline for the design of new circuits as well as to assess the performance of existing circuits.

Үйлчилгээ

Ball milling: a green technology for the

网页The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentally-friendly, cost-effective technique, it has found wide

Үйлчилгээ

Model:Bond/Barratt SABC Models - SAGMILLING.COM

网页2022year4month19day Bond/Barratt Specific Energy Consumption SABC Model. This is a SAG or AG mill plus ball mill model that estimates the overall circuit specific energy consumption using the classical Bond work index equation for multi-stage crushing and single-stage ball milling (E ssbm) including Rowland efficiency factors.The circuit E total is equal to the E

Үйлчилгээ

Ball Mill - an overview ScienceDirect Topics

网页Conical Ball Mills differ in mill body construction, which is composed of two cones and a short cylindrical part located between them (Fig. 2.12).Such a ball mill body is expedient because efficiency is appreciably increased. Peripheral velocity along the conical drum scales down in the direction from the cylindrical part to the discharge outlet; the helix

Үйлчилгээ

Measurement of electrical energy consumption in a Bond

网页2011year1month1day The digital energy meter was previously tested and evaluated in Bond ball mill Work Index testing where direct measured comminution energy of ores processed in the Bond ball mill were compared ...

Үйлчилгээ

GMSG GUIDELINE: DETERMINING THE BOND

网页2018year2month20day closing screen for the ball mill test one (standard square root of 2 series) mesh size coarser than the plant ball mill circuit P80. If between standard mesh sizes, the finer of the chose two. Results of Bond ball mill tests conducted with closing screens of 75 µm or finer are to be treated with caution. The

Үйлчилгээ

Energy Use of Fine Grinding in Mineral Processing

网页2013year12month18day Fine grinding, to P80 sizes as low as 7 μm, is becoming increasingly important as mines treat ores with smaller liberation sizes. This grinding is typically done using stirred mills such as the Isamill or Stirred Media Detritor. While fine grinding consumes less energy than primary grinding, it can still account for a substantial part of a mill’s

Үйлчилгээ

Optimizing Raw Mills Performance ; the Materials WAY

网页2019year6month22day The higher the bond factor for the mill (i.e. Actual kwh/tonne over Bond predicted kwh/tonne) means the mill is less efficient. BALL MILLS ARE NORMALLY ABOVE 1.0 WHILST VSMs ARE LESS THAN 1.0 ...

Үйлчилгээ

Solvent-Free Asymmetric Anhydride Opening in a Ball Mill

网页2007year2month10day The mechanochemical technique of ball milling has been applied to the asymmetric opening of meso-anhydrides, mediated by the cinchona alkaloid quinidine. A simple workup procedure affords the products, optically active dicarboxylic acid monoesters, in high yields, with up to 64% ee. With most substrates no column chromatography was

Үйлчилгээ

Performance comparison of stirred media mill and ball

网页2022year2month20day In this study, samples of bauxite whose chemical composition and Hardgrove Index values are known were ground to micronized size by a laboratory scale stirred media mill and its performance was compared with a laboratory scale ball (Bond) mill. Stirred media mill decreased bauxite d 50 size from 780 to 5 µm in 3 min. But, the ball

Үйлчилгээ

Ball milling: a green technology for the

网页The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentally-friendly, cost-effective technique, it has found wide

Үйлчилгээ

AMIT 135: Lesson 7 Ball Mills Circuits –

网页For overflow ball mills, the charge should not exceed 45% of the mill volume . For grate discharge mills, the charge should occupy about 50% of the mill volume . Bond developed a relationship that can be used to determine

Үйлчилгээ

Model:Bond/Barratt SABC Models - SAGMILLING.COM

网页2022year4month19day Bond/Barratt Specific Energy Consumption SABC Model. This is a SAG or AG mill plus ball mill model that estimates the overall circuit specific energy consumption using the classical Bond work index equation for multi-stage crushing and single-stage ball milling (E ssbm) including Rowland efficiency factors.The circuit E total is equal to the E

Үйлчилгээ

Model:Bond-Rowland SSBM - SAGMILLING.COM

网页2022year3month6day Bond/Rowland Single Stage Ball Mill Model. This is a multi-stage crushing plant feeding a ball mill model that estimates the specific energy consumption (E BM) using the Rowland interpretation of the classical Bond work index equation including Rowland efficiency factors. Testwork Required. Bond ball mill work index; Bond rod mill work index

Үйлчилгээ

Improved characterisation of ball milling energy

网页2019year10month11day Two surveys of the ball mill operating at different conditions found that milling efficiency could be improved by 20%. These results highlight the importance of the mills operating conditions on energy ... The Bond Ball Mill Work index (BBWi) is the industry standard procedure for assessing the grindability of ores. The test involves conducting ...

Үйлчилгээ

Solvent-Free Asymmetric Anhydride Opening in a Ball Mill

网页2007year2month10day The mechanochemical technique of ball milling has been applied to the asymmetric opening of meso-anhydrides, mediated by the cinchona alkaloid quinidine. A simple workup procedure affords the products, optically active dicarboxylic acid monoesters, in high yields, with up to 64% ee. With most substrates no column chromatography was

Үйлчилгээ

Performance optimization of an industrial ball

网页The energy consumption in the ball mill was found to be 6.5 kWh/t of ore with a targeted product size below 1 mm. The BWI of the ores varied from 5.8 to 7.8 kWh/t to reduce the particle size below 100 μ m, but in real

Үйлчилгээ

Design, Construction and Performance Analysis of a 5

网页2017year8month4day Since for the ball mill design we are using 80% passing, the required value of C2 for the ball mill will be equal to1.20. C3 is the correction factor for mill diameter and is given as; 𝐶𝐶3 = 2.44 𝐷𝐷 0.2 (3) However, it is important to note that C3 =0.914 vessel used in producing the ball mill was got from a

Үйлчилгээ

Method of assessing ball mill health - SAGMILLING.COM

网页A Bond ball mill grindability test was performed at the Dawson laboratory on a sample of SAG mill feed collected at the time of the survey. Table 1 – Ball mill grindability test ... A ball mill grinding efficiency above 80% is considered “good”; the measured efficiency of 95% is “very good”. This suggests that the ball mill is ...

Үйлчилгээ

- Конусная дробилка simmons для продажи в США

- Шлифовальный камень Малайзия

- Дробилка используемого в цементном заводе дробилка Китай

- производитель щековая дробилка Индонезия

- вторая рука никелевой руды конусная дробилка

- fungsi Щековая дробилка Индонезия

- стоимость оборудования для подачи медной руды

- шаровая мельница обжига для гипса Индии

- Концентратор добыча руды процесс

- конусная дробилка для продажи в норвегии

- камень дробилка оборудование

- железной руды дробилка в шахтах

- станки фрезерные станки

- гидравлическая конусная дробилка иран

- добыча угля в индонезии преимущество